When it comes to creating the right atmosphere in our spaces, LED light strips are a game-changer. Not only do they provide delightful and energy-efficient lighting, but they also offer unparalleled customization to fit every corner, cabinet, or alcove. So, can you cut LED light strips to suit your needs? Absolutely. Customizing your lighting by safely cutting LED strips allows you to transform any room into a tailored luminary experience. However, to maintain safety and avoid damage to the lights or yourself, knowing the precise process is crucial. Let’s illuminate the path to customizing your LED light strips without a hitch.

Key Takeaways

- LED strip lights are versatile and customizable for any personal lighting project.

- It’s essential to cut only at the manufacturer-designated cutting points to preserve functionality.

- Ensuring safety by disconnecting the power source before cutting is a must.

- The use of the right tools, such as a sharp utility knife or scissors, guarantees a clean cut and long-term durability.

- Adhering to the guidelines and employing proper techniques can enhance your lighting without compromising safety or quality.

- Understanding the structure of LED strip lights is important for successful customization.

- By carefully preparing and measuring, we can achieve precise customization of LED lighting in our projects.

Can You Cut LED Light Strips?

As enthusiasts in LED light customization, we’re often asked, “How to cut LED light strips?” It’s imperative to understand that while LED strip lights are inherently designed for flexibility and customization, not all varieties offer the same ease of personalization. It is true that many LED strips come prepared with designated cutting points—pre-determined spots that safely allow alteration of length without risking the functionality of the lights. However, some LED light strips come with delicacy; for instance, Govee RGBIC strip lights come equipped with individual IC chips. These chips make customization a tricky task because improper cutting could render the entire strip inoperative.

Before we initiate any trimming, it’s crucial to consult the product specifications. Doing so helps us determine whether the model in question accommodates cutting, and if so, where those critical points are located. If you visualize an LED strip, you’d notice cut lines, often represented by a dotted line or scissor symbols, indicating safe zones for alteration. By identifying and using these markers, our objective to safely customize the LED strips to satisfy our unique lighting requirements is within reach.

Here’s a table that succinctly highlights key considerations when deciding if you can customize your LED light strip via cutting:

| Type of LED Light Strip | Cuttable at Designated Points | Special Considerations |

|---|---|---|

| Standard LED Strips | Yes | Marked intervals for easy customization |

| Govee RGBIC LED Strips | No | Individual IC chips require no cutting |

| Waterproof LED Strips | Yes, but with caution | Ensure waterproofing integrity post-cut |

Remember, your venture into LED light customization should start with a thorough understanding of your product and its capabilities. Confirming the design specifications not only preserves the life span of your LED strips but also ensures that they continue to brighten our environments just as intended.

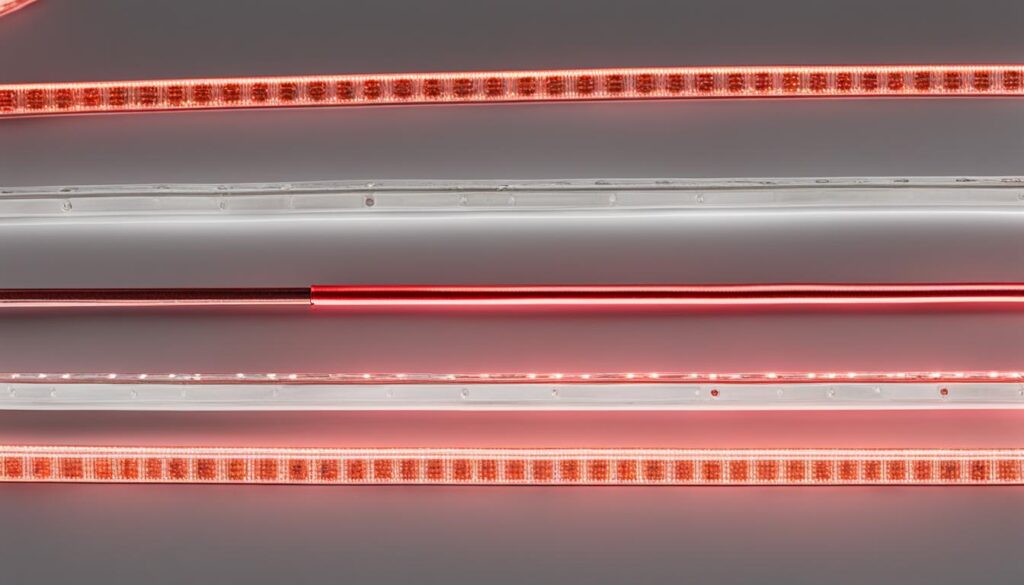

Understanding LED Strip Lights and Their Structure

We recognize that LED strip lights are a flexible and popular lighting solution for both residential and commercial spaces. To fully appreciate and correctly harness the potential of these lights, it’s essential to delve into the LED strip light structure itself. Adequate knowledge of the structure aids in ensuring you make precise alterations without damaging the product.

What Makes up an LED Strip Light?

The anatomy of an LED strip light is rather ingenious yet simple. At its core, the strip consists of multiple LED chips, which are mounted onto a flexible circuit board. This kind of lighting system is designed to be both versatile and robust, courtesy of a protective layer that also enables the strip to maintain flexibility. This protective coating is vital as it ensures the light can be bent to conform to different shapes and surfaces without the compromise of LED chips.

Where Are the Cutting Points on LED Strips?

For those of us intending to tailor our LED strip lights, identifying the designated cutting points on LED strips is a critical step in the customization process. These points are part of the pre-fabricated design and are clearly indicated to guide users on where the strip may be safely cut. Typically, these points are located in proximity to copper pads or dots, providing a visual marker as to where cutting the strip will not disrupt its function.

| Feature | Description | Considerations |

|---|---|---|

| LED Chips | Small diodes that produce light when current passes through them. | Avoid contacting directly to prevent damage. |

| Flexible Circuit Board | Base material that holds LED chips and allows bending. | Flex with care; overbending can damage internal circuitry. |

| Protective Coating | Transparent layer that shields LED chips and circuitry. | Ensure coating is not compromised during cutting for continued protection. |

| Cutting Points | Designated areas indicated for safe alterations. | Always cut at these points to maintain LED strip integrity. |

Now that we have understood what composes an LED strip light and where the safe cutting regions are, we ought to proceed with the modifications with confidence, knowing these elements are crucial for a successful, custom fit into our lighting projects. When we use the cutting points marked on our LED strips, we preserve the essential structure, securing both the aesthetic and functionality of our lighting.

Preparing to Cut Your LED Light Strip

Embarking on the process of cutting led light strips requires not just the right tools, but also the right methodology. Before you make that crucial snip, let’s take a moment to outline the steps to ensure your LED light strip modification is done both successfully and safely.

- Measure the Length: Use a ruler or measuring tape to define the exact length needed for your application. It’s not just about cutting; it’s about cutting to fit your unique space and design vision with precision.

- Identify Cutting Points: Carefully review the strip and locate the manufacturer’s marked cutting points. These are your guiding beacons to customize without compromising the strip’s functionality.

- Disconnect Power Source: Safety first – ensure that your LED strip is completely unplugged from any electrical source to avoid the hazards of electric shock.

- Prepare Your Cutting Tool: Whether it’s a pair of fine scissors or a utility knife, your cutting instrument should be sharp and ready to make a clean sweep along the indicated line.

In the realm of personalizing your living or workspace, these preparation steps serve as an insurance policy against errant cuts and avoidable errors. They establish foundations, ensuring that your final product – the vibrant, uniquely tailored illumination you envision – achieves its full potential.

Preparation is just as essential as the physical act of cutting when it comes to modifying LED light strips. Neglecting this can lead to irreparable mistakes, risking both your safety and the project’s success.

With a composed attitude and these precautionary measures in place, the path to personalizing your space with LED lighting is clear. Trust in these preparative steps as you would a roadmap; they are key to not just a successful installation but also to unleashing the creative potential LED lighting affords.

Our journey of customization doesn’t end after the cut is made. Stay tuned as we delve into the topic of picking the proper tools for slicing through those bright lengths of potential – an indispensable part of the LED strip cutting experience.

The Right Tools for Cutting LED Strips

When embarking on a project that involves customizing LED lighting, the importance of using the proper tools for cutting LED strips cannot be overstated. This critical step ensures not only the precision of your customization but also the safety and continued functionality of your LED strips. Let us delve into the essential tools that make a significant difference in achieving a clean, accurate cut.

Essential Tools Needed for a Clean Cut

To carry out a flawless custom cut of your LED strips, a very specific set of tools is required. Paramount among these are sharp scissors for LED cutting or a finely-honed utility knife. These instruments must be capable of slicing through the silicone coating and circuit board with ease, allowing for a neat separation without causing any fraying or damage to the integral components of the strip.

Why Quality Cutting Instruments Matter

The longevity and effectiveness of your LED strips post-cut hinge heavily on the quality of the cut made during customization. A jagged or imprecise cut can not only spoil the aesthetic appeal but may also result in a malfunctioning light strip. Therefore, it’s worthwhile to invest in high-quality cutting tools—doing so ensures a better outcome and preserves the integrity of your lighting project.

- Sharp scissors or utility knife for a precise cut

- Soldering iron for reattaching any necessary wires

- Additional cutting mat to protect surfaces and maintain stability

Remember, the aim is not merely to modify an LED light strip but to customize it in such a way that it complements your space and serves its purpose reliably for years to come. That’s why we emphasize the necessity of utilizing the right tools for the job.

The Step-by-Step Guide to Cutting LED Light Strips

Embarking on the journey to customize LED strip length is made significantly easier with a clear, step-by-step LED strip cutting guide. As experienced enthusiasts in the realm of LED strip customization, we have distilled the process into manageable steps that lend to precision and optimal functionality. Let us delve into the methodology that ensures your lighting meets the exact requirements of your space.

Firstly, the preparation stage is crucial. We recommend laying the LED strip flat on a stable surface and pinpointing the precise cutting line. Once identified, it’s time to make the cut. If you have selected a utility knife, apply consistent pressure and slice through the designated point to bypass any rough edges that may arise. In the event that scissors are your tool of choice, aim for a swift, straight cut to prevent fraying.

Below, you’ll find a table that summarizes the tools and techniques necessary for each corresponding action:

| Action | Tool | Technique |

|---|---|---|

| Measuring and Marking | Measuring Tape or Ruler | Align with cut line and mark clearly |

| Cutting with a Utility Knife | Utility Knife | Slice with steady pressure across the full width |

| Cutting with Scissors | Scissors | Make a straight, swift cut |

To sum up, when you customize LED strip length, remember that the key is accuracy and a steady hand. By giving heed to the detailed steps and using appropriate tools, you can alter the dimensions of your LED light strip without damaging its structure or performance. This ensures you retain both the aesthetic and functional aspect of your LED lighting setup, customized to perfection for your environment.

Best Way to Cut LED Light Strips

When we talk about the best way to cut LED light strips, we’re focusing on precision and protection. Ensuring the longevity and performance of LED lights involves more than just a steady hand; it requires understanding the structure of your strip lights and respecting the manufacturer’s designated cutting areas.

Finding the Correct Cut Line

Locating the correct line for a perfect LED strip cut is the first crucial step for us. Typically, the cut lines are denoted by scissors icons or dashed lines, indicating safe zones for alterations. These markings are our roadmap to customization, allowing us to adjust the length of the LED strip without damaging its intricate circuitry. Before making your cut, always ensure that these guidelines are being followed to avoid potential malfunctions.

Tips for a Straight and Even Cut

To achieve the ideal cut, there are some tips we should always keep in mind. First, use tools that are specifically designed for cutting LED strips or a sharp pair of scissors. Cutting directly through the center of the copper pads will give us the best results. Applying steady and gentle pressure, while ensuring that the strips are on a firm and stable surface, will help us avoid jagged edges or damage that could affect performance.

| Step | Description | Outcome |

|---|---|---|

| 1. Identify Cutting Marks | Locate the scissor icons or dashed lines on the strip | Clean and safe area for cutting identified |

| 2. Use the Right Tool | Select a sharp pair of scissors or cutting tool | Precision in cutting, avoiding damage to LEDs |

| 3. Cut at the Center of Copper Pads | Position the tool at the center of the pads to cut | Ensures continued functionality of the strip |

| 4. Apply Gentle Pressure | Cut with care to avoid bending the strip | Even edges and a straight cut |

By incorporating these guidelines into our practice, we ensure that we’re utilizing the best way to cut LED light strips and maintaining their optimal functionality. With each perfect LED strip cut, we extend the life and enhance the application of our LED lights.

Safety First: Cutting LED Strips Without Getting Hurt

When we talk about customizing your lighting, safely cutting LED strips is a crucial step in the process. Proper LED strip cutting safety measures ensure not only our well-being but also the functionality of the LED strips post-modification. In this guide, we emphasize the importance of safe handling techniques and protective equipment.

First and foremost, ensure that all power to the LED strip is disconnected. This is an essential step to prevent any electrical shock during the cutting process. Here are some additional safety tips:

- Use the right tools: A sharp utility knife or a pair of scissors will provide you with a clean cut and prevent damage to the strip.

- Wear safety gear: Put on protective gloves and safety goggles before making any cuts to shield yourself from sharp edges and flying debris.

- Apply appropriate pressure: Avoid exerting excessive force that could twist or bend the strip, leading to potential damage.

By following these guidelines, we ensure a safe environment and uphold the quality of our lighting project. Remember, a successful customization not only looks good but is also performed safely.

Tips for Cutting LED Light Strips

When indulging in the customization of LED light strips in our projects, we’re often poised with the task of cutting these strips to size—a delicate process filled with potential for error. The key to success is adherence to a handful of resourceful best practices that help in avoiding common LED strip cutting mistakes. It begins with understanding how to measure and mark accurately and culminates with handling the LED strips post-cutting with care.

How to Avoid Common Cutting Mistakes

Precise measurement is our starting line; always measure the length needed twice to avoid any irreversible errors. Firmly mark your cut points, ensuring they coincide with the manufacturer’s designated cutting areas. A helpful tip for cutting LED light strips right is to lay them on a stable, flat surface to guarantee an even, straight cut. Consider using a rigid ruler along the cut line as a guide to avoid uneven edges.

Handling the Strips After Cutting

Once you’ve successfully made the cut, how we handle our LED strips is pivotal in maintaining their performance. Gently flexing the strip should be done at a minimum to prevent damage to the newly cut ends, which could potentially result in lighting or connectivity issues. Don’t forget to inspect the strip for any signs of fray or tear, and always double-check your connections, confirming that they’re secure and correctly aligned.

Below, find a useful table that outlines common mistakes and how to avoid them during your LED strip cutting endeavors:

| Common Mistakes | Preventive Measures | Tips for Proper Handling |

|---|---|---|

| Not measuring accurately | Use a ruler or measuring tape; mark twice before cutting. | Secure LED strip on a flat surface while cutting. |

| Cutting outside designated points | Cut strictly on manufacturer’s indicated cut points. | Avoid bending LED strip excessively at cut points. |

| Using blunt cutting tools | Ensure cutting tools, like scissors or knives, are sharp. | Handle the strip without putting strain on cut ends. |

| Connections not secure after cutting | Check all connections are snapped or soldered properly. | Test LED strip functionality before final installation. |

In conclusion, by learning and applying these straightforward tips for cutting LED light strips, you empower yourself to personalize your lighting solutions meticulously while successfully avoiding LED strip cutting mistakes. The process is as crucial as the product, and a meticulous approach ensures both aesthetic allure and optimal functionality.

When Cutting Goes Wrong: Troubleshooting LED Strip Issues

In our experiences with LED strip lighting, we have encountered scenarios where troubleshooting led strip issues became necessary. One common issue arises when reconnecting cut LED strips. The integrity of the electrical connection is paramount, and if the strip isn’t illuminating after being cut, the first step is to examine the copper contacts at the ends. These contacts must be intact and clean to ensure effective current flow.

Another critical aspect is confirming the polarity—the positive and negative orientation of the connections. This might seem like a minor detail, but incorrect polarity is a leading cause of strip malfunction post-cutting. If everything appears to be in order but the strip still isn’t working, testing with another power supply or strip segment can help identify whether it’s a power issue or a problem with the strip itself.

Connections, especially those that have been soldered, should be sturdy and secure. Loose connections might not be visually apparent, so a meticulous re-examination is sometimes necessary. If using clip-on connectors, make sure they have been firmly closed to avoid any flickering or partial lighting of the LED strip.

Below, we present a quick checklist to walk you through the most common troubleshooting steps when you’ve hit a snag with your cut LED strips:

- Check for visible damage to the copper contacts at the strip’s ends.

- Confirm that the polarity is correct when reconnecting the cut ends.

- Test the LED strip with an alternative power source if available.

- Ensure all connectors are snug and fully closed.

- Inspect soldered connections for any weak spots or breaks.

While setbacks can occur in the process of customizing your lighting, these troubleshooting steps are usually sufficient to rectify the situation. When done with care, reconnecting cut LED strips can prolong the life and enhance the versatility of your LED strip lighting solutions.

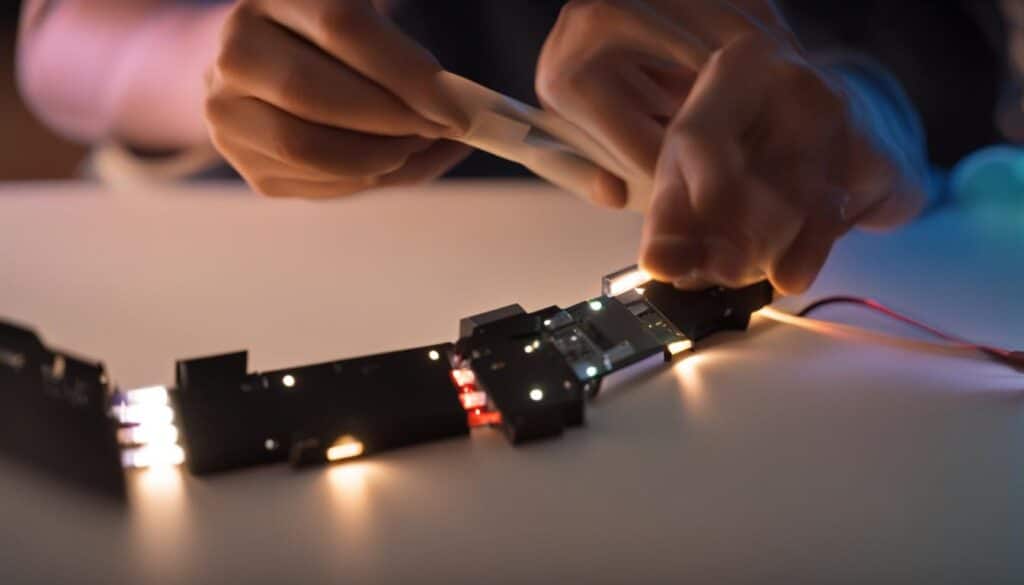

Reconnecting LED Strips After Cutting: A How-To

Once you’ve mastered cutting your LED strips to the desired length, the next step is to transition into reconnecting LED strips. This ensures the luminosity continues across the length of your design without interruption. Whether you are extending your lighting setup or creating angles, the method of reconnection is crucial for a seamless operation. We will delve into the techniques for a safe and effective reconnection, so your customized lighting maintains its brilliance and functionality.

Soldering vs. Using Connectors

When reconnecting your cut LED strips, you can choose between soldering for a permanent bond or using LED strip connectors for a quick and easy connection. Soldering provides a sturdy and reliable connection but requires technical skill and equipment. On the other hand, LED strip connectors, available in various shapes such as T, L, or straight line, offer a more user-friendly and flexible solution.

For those who prefer not to wield a soldering iron, LED strip connectors are the go-to. These small but mighty accessories come in handy to effortlessly join LED strips together. They are designed to maintain the aesthetic and functionality of your lighting without the need for any complex equipment.

Ensuring a Reliable Connection

To guarantee a strong and consistent electrical connection, there are certain steps we must follow. Initially, peeling back the adhesive backing with care to reveal the LED strip’s contacts is essential. Then, precisely align the copper dots with the connector’s pins or clamps. This finesse assures complete engagement and optimal conduction.

When closing the connector over the LED strip, gentle pressure is needed. Too much force can lead to damage to the delicate LEDs or circuitry—something we diligently avoid. Following these steps is critical for preserving the life-span of your lighting and obtaining that polished look.

Lastly, a thorough testing phase is indispensable post-reconnection. This stage confirms the successful restoration of light flow and the integrity of the LEDs. By assuring a solid, secure connection, we safeguard the performance of our customized LED arrangement, so it continues to brighten our spaces exactly as we intended.

Creative Applications for Custom-Cut LED Lighting

Our ingenuity truly shines when we explore the creative uses of LED strip lights in our living spaces and beyond. The versatility of custom-cut LED lighting applications is boundless, transforming ordinary areas into vivid and exhilarating environments. One notable application is utilizing LED strips as a safety enhancement with staircase edge lighting, that doubles as a modern design feature. In the bedroom, the idea of tranquility meets style with LED headboard backlighting, offering an intimate ambiance that also serves as a nightlight.

Witness the transformation of personal grooming spaces as mirrors become captivating focal points when framed with soft, luminous LED lighting. They’re not just for aesthetics; these customized lights provide practical task lighting that is perfect for makeup application or a morning shave. Likewise, furniture can assume a fresh dynamism; envision the subtle sophistication of a couch or bed accented with LEDs beneath, projecting a gentle glow that elevates the room’s appeal.

For those enamored with technology integration, custom-cut LED solutions can sync with smart home systems, facilitating features like voice activation and app control for versatile lighting scenarios. Think of dynamic colors shifting at your command during a house party, or the convenience of scheduled lighting changes to match your daily routines.

- Customized car interiors that reflect personality

- Themed party ambiances with vibrant, color-changing sequences

- Subtle under-shelf lighting to showcase collectibles

Nonetheless, the real beauty of custom-cut LED lights is not just in the myriad of applications, but in the personal touch that they bring to our environments. They are the perfect merger of function and flair, providing both utility and an expansion of our creative horizons.

| Location | Application | Effect |

|---|---|---|

| Staircase | Edge Lighting | Safety and Aesthetics |

| Bedroom | Headboard Backlighting | Ambiance and Comfort |

| Living Room | Accent Lighting | Style and Sophistication |

| Automobile | Interior Customization | Personalization and Style |

In summary, custom-cut LED strip lights stand out as a resourceful and innovative tool for both homeowners and enthusiasts alike. Their adaptability to numerous scenarios makes them a smart choice for anyone looking to add a touch of personalized brilliance to their world.

Conclusion

Customizing your space with LED light strips represents the intersection of technology and personal creativity. Cutting LED light strips offers a versatile solution that empowers us to tailor lighting fixtures to our precise specifications. By rigorously adhering to the guidelines recommended by manufacturers, we can ensure a safe and accurate customization of our LED light strips to align perfectly with our envisioned designs.

Whether our aim is to elevate the ambiance of our homes, innovate with one-of-a-kind commercial displays, or add a personal touch to our vehicles, the customization of LED light strips serves as a potent tool for expressive lighting design. The informative steps we’ve outlined throughout this guide aim to facilitate a smooth transition from standard LED strips to personalized components of your environment, be it for practical or aesthetic applications.

Our journey with LED light strips doesn’t conclude here. Should you find yourself needing further guidance, or if you’re inclined to share your experiences and insights regarding LED light strips customization, your contributions are welcome in the comments. Let us continue to learn from one another and enable our joint exploration of cutting LED light strips to illuminate our paths ahead.

FAQ

Can You Cut LED Light Strips?

Yes, you can cut LED light strips at certain intervals, typically where you see the marked cutting points that are designated by the manufacturer. These points may be indicated by a dashed line or scissor icons.

How Do You Cut LED Light Strips Safely?

To safely cut LED strips, first ensure the strip is disconnected from power. Then measure and mark the spot you wish to cut, always making sure it aligns with the marked cutting points. Use a sharp pair of scissors or a utility knife for a clean cut, and practice good safety measures throughout the process.

What Makes Up an LED Strip Light?

An LED strip light consists of small LED chips placed on a flexible circuit board and encased in a protective coating, allowing for flexibility without damaging the components.

Where Are the Cutting Points on LED Strips?

The cutting points on LED strips are usually found at regular intervals along the strip and can be identified by cut-line markings, like dashed lines or scissor symbols, near copper dots or pads.

What Tools Do I Need for Cutting LED Strips?

You’ll need a sharp pair of scissors or a utility knife for the actual cutting, and possibly a soldering iron if you plan to attach wires after cutting. A ruler or measuring tape can help ensure accurate measurements.

Why Are Quality Cutting Instruments Important?

Quality cutting instruments are essential to achieve a precise and clean cut, which is vital to maintaining the integrity and functionality of the LED light strip after the modification.

How Can I Achieve a Perfect Cut on My LED Strip?

The best way to achieve a perfect cut on an LED strip is to first find the correct cut line and then use a sharp cutting tool to slice cleanly through the center of the copper pads at this point.

What Are Some Tips for a Straight and Even Cut?

To ensure a straight and even cut, use a ruler or measuring tape to mark the exact point where you will cut, align the tool properly, and apply steady pressure while using sharp scissors or a utility knife.

What Safety Measures Should I Take When Cutting LED Strips?

Always disconnect the strip from the power source before cutting, use sharp tools with care, and consider wearing safety gear like gloves and protective goggles to prevent injury.

How Do I Avoid Common Mistakes When Cutting LED Strips?

To avoid common mistakes, measure twice and cut once, always at the designated cutting points. Handle the LED strip carefully after cutting to prevent damage to the cut ends or circuitry.

How Should I Handle LED Strips After Cutting?

Handle cut LED strips gently, being careful not to bend or apply too much pressure on the cut ends. Ensure any connections made after cutting are solid and secure.

What Do I Do if My LED Strip Does Not Work After Cutting?

If your LED strip doesn’t work after cutting, check for potential damage at the cut ends or copper contacts, ensure proper polarity if you’ve reconnected the pieces, and test the power supply. If using connectors, make sure they are securely closed.

Soldering vs. Using Connectors: Which Is Better for Reconnecting LED Strips?

The choice between soldering and using connectors depends on your comfort level with soldering and the specific use case. Connectors are typically simpler and quicker for most people, while soldering provides a more permanent and robust connection.

How Can I Ensure a Reliable Connection When Reconnecting LED Strips?

To ensure a reliable connection, carefully expose the copper contacts before using connectors, secure the connection firmly without damaging the LEDs, and test the reconnected strip for proper functionality.

What Are Creative Applications for Custom-Cut LED Lighting?

Custom-cut LED lighting can be used for a variety of creative applications, from enhancing home décor like staircases and headboard backlighting, to innovative commercial displays, to personalizing car interiors. They can also be integrated into smart home systems for customized, voice-activated, or app-controlled lighting schemes.