“`html

When we focus on brightening the night with LED light bars, we don’t merely seek that vibrant glow; we’re also striving for superior safety and impressive performance. However, let’s be honest—determining which gauge wire for 12v led light bar to utilize is a crucial aspect of that radiant puzzle. We’re discussing that ideal range, the recommended wire gauge for 12v led light bars, which guarantees our lights will illuminate effectively without our configurations igniting into a fireworks display.

It’s not just about picking a flashy wire; it’s about tuning into that ideal gauge where the flow of electrons is just right—akin to the harmony of a finely tuned instrument. Choose poorly, and you might be calling the fire department. But stick with us, and we’ll demystify the electrical setup for LED light bars, explaining why the gauge of your wire can either support or sabotage your bright aspirations. And we won’t stop there! We’ll shine a light on safety in wiring for LEDs because nobody desires an unexpected light show filled with sparks indoors. Let’s get wired up properly, securely, and let those LEDs perform their best—glow!

Key Takeaways

- Selecting the right wire gauge is essential for both functionality and safety.

- Optimal wire gauge ensures LED light bars function without overheating complications.

- Electrical setup for LED light bars requires a careful balance of current flow and wire thickness.

- The safety in wiring for LEDs is critical—using the correct gauge brings peace of mind.

- Diving into wire gauge specifics can avert potential fire risks and guarantee an eye-catching display.

Grasping the Fundamentals of Wire Gauge and Its Importance in LED Lighting

Let’s be real, when we’re setting up those striking LED light bars for our trucks, ATVs, or backyard spaces, we frequently neglect something seemingly simple yet incredibly vital—the wire gauge. The wire gauge for 12v led light bar we choose is not only about activating the lights; it’s about maximizing electrical efficiency and ensuring our stunning arrays of LEDs shine brightly without an unwelcome background of fizzles and pops.

The American Wire Gauge (AWG) system is the unsung champion behind our electrifying endeavors. Those critical wires resemble the veins of our LED lighting electrical systems, transporting electrons back and forth. Our reliable ally, the lower the number, the thicker the wire. A straightforward rule with high stakes; choosing incorrectly is like anticipating a light display with all the excitement but for all the wrong reasons.

The Significance of Proper Wire Gauge in Electrical Systems

If we carelessly select wire gauge, we’re inviting predicaments. A wire that is too thin wastes voltage like a leaky faucet; the valuable energy drips away, and our LEDs may flicker like a haunted venue rather than shine like a beacon. And we mustn’t overlook, a wire that’s hotter than our summer cookout is an absolute no-no. We’re talking dangers, not just to our light project, but to everything nearby. Safety first, brightness second.

Distinction Between Solid and Stranded Wires

Here’s where decisions get intriguing. Do we opt for solid or stranded? Simply put, solid wire flexibility is a breeze for straight lines—simple to handle, a snap to install. However, if our path resembles a rollercoaster more than a straightaway, stranded wire complexity has its advantages. More conductors snugged into a warm insulated jacket—it’s akin to providing our current options for its route.

Keep in mind, when discussing wire gauge for 12v led light bar setups, we’re not merely making connections. We’re creating the lifelines of illumination, establishing the foundation for a light display that withstands time and safety scrutiny. A wise choice, informed by the valuable American Wire Gauge system, ensures we remain bright and secure rather than hot and bothered.

What Gauge Wire for 12V LED Light Bar

We’ve all experienced it, eagerly unwrapping our newest 12V LED light bar, envisioning the stunning illumination it will create. But hold your horses—we need to discuss the recommended wire gauge for 12V LED light bar installation first. Selecting an inappropriate wire gauge is akin to attempting to sip a milkshake through a coffee stirrer; it’s not just ineffective, it could lead to disaster.

Let’s delve into the essentials of electrical conductivity and current handling capacity. When it comes to safely energizing your LED light bar, thickness is crucial. Choose too thin, and you’ll create a bottleneck where electricity struggles to flow, resulting in the dreaded voltage drop and putting your setup at risk of overheating.

But worry not, we’re here to guide you through the turbulent waters of resistance and wire choice. Remember, folks, the longer the wire, the more resistance you’ll encounter. Envision it as a long-distance relationship; the farther apart you are, the harder it is to maintain that bond. The same principle applies to your wires—the longer the wire run, the higher the gauge required to keep that current snug and safe. Ready for the essentials? Here’s a summary:

| Length of Wire (Feet) | Recommended Wire Gauge (AWG) |

|---|---|

| 0 – 4 | 16 |

| 5 – 7 | 14 |

| 8 – 10 | 12 |

| 11 – 13 | 10 |

| 14 – 17 | 8 |

| 18+ | 6 |

It’s like selecting the ideal pair of socks. Too tight and you’re uncomfortable all day; too loose and you’re waddling like a penguin with each step. Finding that ‘perfect’ wire gauge ensures a warm, comfortable feeling overall—safe, efficient, and fully operational. So, before diving into that electrifying journey of LED light bar installation, invest in quality wire. It’s the silent protector of your dazzling pride and joy.

We advise, choose wisely, guarantee capacity, and let the light shine brightly, safely, and soundly!

Assessing the Current Load and Voltage Drop for 12V LED Light Bars

Selecting wire gauge isn’t an aspect we can afford to guess; when it comes to our LED light bar wire selection, accuracy is essential. Why? Because the wire capacity for 12v led light bar systems dictates their performance, and nobody desires a weak light any more than they want a fried electrical system.

Why Does Wire Gauge Matter for Current Load?

Picture a water pipe; the broader it is, the more water flows through it effortlessly. The same concept applies to wires concerning optimal electrical conductivity for LEDs. A thicker gauge provides a higher wire capacity to handle current, significantly reducing the chance of turning our lights into an unintended barbecue feature. Grasping resistance and ohm in wiring, fundamentally, helps us stop our LEDs from underperforming or overheating.

Combatting Voltage Drop in Long Wire Runs

Driving voltage across an extended wire is much like instructing a child to complete a marathon — you’re likely to observe a slowdown. A greater resistance in wires,

“““html

especially those that are more slender and longer, leads to an undesirable voltage decrease, dimming our brilliant LED light bars, undermining the ambiance, and potentially the utility too. Additionally, our off-road paths won’t appear as remarkable when poorly lit.

| Wire Gauge (AWG) | Max Current (Amps) | Recommended Max Run Length (ft) | Resistivity (Ohms) |

|---|---|---|---|

| 18 | 10 | 10 | 6.385 |

| 16 | 13 | 15 | 4.016 |

| 14 | 17 | 20 | 2.525 |

| 12 | 20 | 25 | 1.588 |

| 10 | 30 | 35 | 1.000 |

Size is crucial, my friends, and nowhere is this more evident than in a dependable 12V system for our glorious LEDs. Thus, before we engage in electrical work, let’s ensure our LED light bar wire selection aligns with the wire gauge capable of managing our current load and eliminating voltage drops. We don’t seek to dim the brilliance of progress but to illuminate brightly and safely into the future of LED lighting.

Selecting the Appropriate Wire Type for Your Lighting Project

When it comes to brightening our areas with a 12V LED light bar, we aren’t simply plugging in an elegant bulb and calling it a day. Oh no, we need to craft the entire experience, starting with selecting the right wire — it’s akin to choosing the perfect guitar string for ideal pitch. Now, do we opt for a solid solo or a stranded symphony? Let’s dive in and explore the advantages and disadvantages.

Comparing Stranded vs. Solid Wire for 12V LED Applications

The initial contender in our electrical lineup is the stranded wire. Consider it the agile gymnast of wires, all about that flexibility—incredibly useful when you’re navigating your lighting through twists and turns. But what about its counterpart, the solid wire? This fellow is the straightforward one, embodying simplicity, making connections a breeze thanks to its reliable nature.

So, should we embrace the stranded wire benefits when addressing a winding path, or does the solid wire connection ease suit us better? Stick around as we examine the setlists:

- Wire Diameter for 12V LED Light Bar: Are we playing a grand venue or an intimate acoustic session? Similarly, we need to align wire diameter with the power demands and lengths of our light bars.

- Stranded Wire Benefits: Just like a musical group, stranded wires combine numerous small conductors, allowing easy maneuvering around corners or compact setups without breaking a sweat.

- Solid Wire Connection Ease: Solid wires are like a solo act; they steadfastly maintain their shape, which is fantastic when a straight run is desired with little hassle.

Considerations for Flexibility and Installation Ease

We cherish simplicity, don’t we? While both stranded and solid wires could headline our lighting performance, each has its unique style. Our 12V LED wire selection criteria resonate with the essence of our project — is it a complex setlist with plenty of movement, or a straightforward rock anthem? Solid wires may dominate the latter, but stranded wires excel when the routes become winding.

Ladies and gentlemen, that concludes our discussion on wires — whether you aim to drop the bass with solid lines or add flair with the flexibility of stranded wires, ensure your choice harmonizes with your LEDs. As for us, we’ll continue to groove to the electric rhythm of our lighting endeavors.

How to Determine the Suitable Wire Gauge for Your LED Light Bars

When it comes to lighting up the evening with your dependable 12V LED light bar, understanding the intricacies of wiring can either elevate or hinder your bright aspirations. We’re here to brighten the way to an impeccably powered light display by decoding wire gauges. Strap in, it’s time for a few LED power supply calculations!

Calculating Total Amperage and Wire Length

Put on your calculating hat, my friend! The initial step in our electrifying adventure involves wattage – not the kind that strikes but the kind that you compute. Gather the total wattage of your LED light bar, perform a little division dance with the voltage, and voilà, you’ve determined the current consumption of your setup. Remember, if your LED light bars have hefty appetites, ensure their feeding wire can handle the current they’ll be devouring.

Using a Wire Gauge Chart to Identify Correct Size

Now, don’t get tangled in uncertainty about which sized wire to select; let’s consult the reliable wire gauge chart. This chart is your guiding light in the dark, a brilliant guide that connects the specs between the amperage your LED setup requires and the length of wire you possess. It’s about achieving that ideal point – where the appropriate wire gauge for 12V LED light bars meets minimal resistance and no voltage loss. So, say goodbye to flickering apprehensions and welcome that electrifying clarity!

If you’re eager to explore those charts we keep mentioning, allow us to satisfy your thirst for precision. After all, who doesn’t appreciate a good chart, especially regarding wire gauge chart usage? It’s the Rosetta Stone for interpreting your LED light bar current consumption into wire insight. To ensure you don’t short-circuit your intelligent setup, choose a gauge capable of supporting your entire LED ensemble, and avoid letting overly slim wires dim your bright prospects.

Wire Gauge Size and Its Influence on LED Light Bar Performance

Have you ever pondered why your LED light bar doesn’t glow as brightly as you anticipated? Let us shed light on the matter—it’s likely due to the wire thickness for your 12V LED light bar. It’s not solely about the wattage or the brand of your lights; it’s also about the conduit through which the electrical current flows. That’s right, wire sizing for brightness is a tangible game-changer.

When it involves LED light bar gauge sizing, we’re confronted with a Goldilocks scenario—neither too thin nor too thick, but just right. If you select too thin a wire, expecting your light bar to function efficiently is akin to believing a garden hose can extinguish a house fire. Conversely, picking a wire gauge that’s too thick might lead to over-specifying your needs, similar to using a fire hydrant to water your daisies.

Opting for the correct wire gauge is navigating the ship of electrical performance factors in the right direction, with the brightness of your LED light bar shining like a lighthouse on a dark night.

- For short distances, 14-gauge wires might suffice.

- However, if you’re installing over the length of a limousine, or say, a fishing boat, 12-gauge could be your best option to keep those LEDs performing as if it’s showtime on Broadway.

The essence of the matter is this: balance. You want to synchronize the wire thickness

“““html

to the requirements of your illumination arrangement, achieving the greatest value (or should we mention brightness?) for your investment. It’s about enhancing efficiency while ensuring safety remains intact.

To aid your comprehension, let’s examine the figures:

| Wire Gauge | Max Current (Amps) | Suggested Usage |

|---|---|---|

| 14 AWG | 15 Amps | Interior lighting, short distances |

| 12 AWG | 20 Amps | Outdoor lighting, longer distances |

So, when you’re determining your wire sizes next time, keep in mind—it’s the quiet element in the backdrop that allows the spotlight to shine at its fullest. Select wisely, for the wire you choose is the illumination you produce.

Frequent Installation Errors with Improper Wire Gauge Selection

We’ve all come across the tales; a weekend task transforming into an unplanned fireworks event. This is precisely why selecting the correct wire gauge for 12v LED light bar is not merely about accuracy—it’s fundamentally about safety. Navigating through the maze of electrical installations, one cannot emphasize enough the significance of wire sizing for safety and overheating prevention. Make no mistake; the incorrect wire gauge doesn’t just reduce your lights’ brightness, it diminishes the whole project.

Before you commence weaving wires, let’s untangle the reality of what transpired when mistakes occur due to improper wire sizing.

The Risks of Overheating and Possible Fire Dangers

There is a fine distinction between a bright space and an actual fire pit. Opting for a wire gauge that is too slender is akin to selecting chopsticks over tongs to extract a potato from the flames. It’s not going to end well. Skinnier wires lead to increased resistance; this results in more heat, and additional heat means a greater risk of overheating and potential fire dangers. Enhancing LED light bar efficiency isn’t rocket science—but it definitely entails avoiding incinerating your setup!

Effects on Light Bar Brightness and Functionality

Ever witnessed a dimly lit amusement park? Neither have we. Why settle for a shadowy visage when you intended for brilliance? Choosing a wire gauge that is too small can lead to a considerable voltage drop that affects the brightness and overall functionality of your LED light bar. Appropriate wire sizing is about allowing the light to do the heavy lifting, not your wires.

| Wire Gauge | Amperage Capacity | Potential Risks for 12V LED Light Bar |

|---|---|---|

| 18 AWG | Up to 10 amps | High resistance, risk of overheating |

| 16 AWG | Up to 13 amps | Moderate resistance, slight chance of voltage drop |

| 14 AWG | Up to 17 amps | Ideal for most LED light bar configurations |

| 12 AWG | Up to 20 amps | Low resistance, minimal voltage drop risk |

Guidelines for Wire Thickness and Installation Methods

As we delve into the essentials of laying the foundation for your innovative 12V LED projects, it’s worth reiterating that when addressing wire gauge recommendations for LED light bars, exceeding the standard practice can yield remarkable results. That extra length of wire or a slight increase in thickness can distinguish between a decent setup and an exceptional one.

Optimal Techniques for Protecting Your LED Light Bar Setup

Ensuring an installation that endures isn’t solely about adhering to the standard 12V LED installation manual; it’s about promoting LED light bar safety through techniques that safeguard both your project and peace of mind. From securing connections to maintaining vigilance on insulating materials – it’s the nuances that determine longevity.

Selecting Wire Thickness That Surpasses the Basic Requirement

It may appear trivial, but in the realm of LED lighting, every fraction of thickness is important. Choosing a wire thickness that exceeds the minimum requirement isn’t just clever—it’s an optimal wire sizing strategy. Consider it the secret ingredient to a lighting arrangement that not only radiates brighter but also endures longer without the fear of a short circuit.

- Double-check the wire gauge versus the anticipated amperage.

- Don’t hesitate to upgrade to a thicker wire if uncertain.

- Recognize that the longer the distance, the more significant wire thickness becomes.

Take these suggestions to heart and apply them carefully to your impending LED project. The outcome? A strong, durable LED light bar setup that shines with assurance.

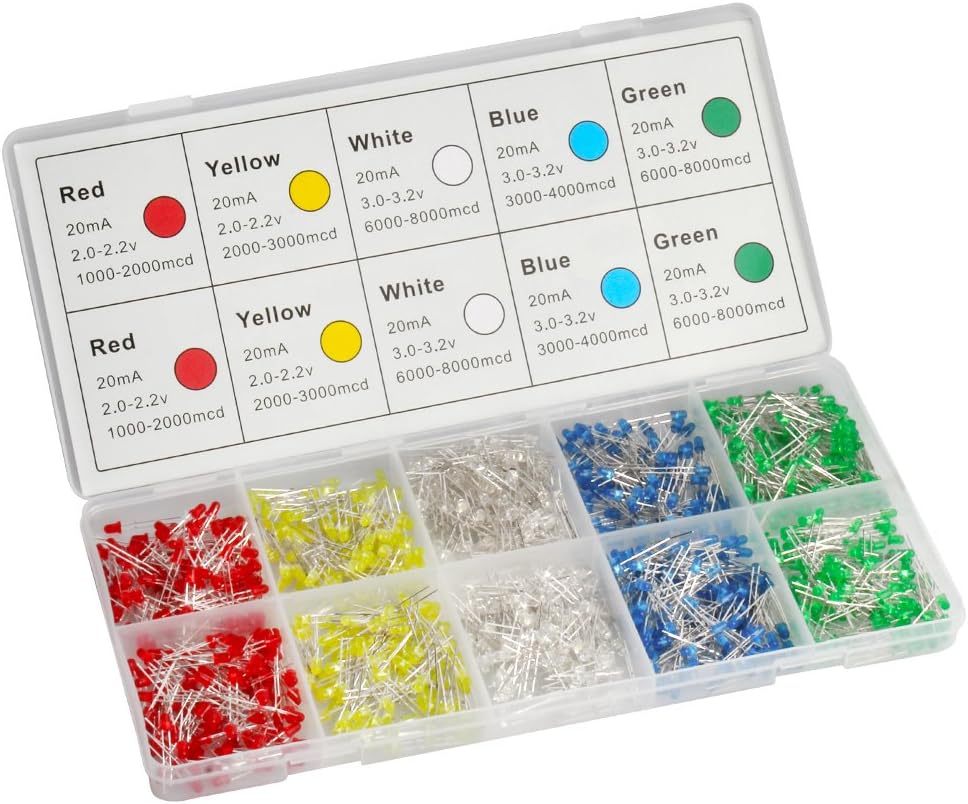

Wire Size and Color Coding for Error-Resistant Electrical Work

When we prepare for some serious wiring tasks—such as equipping our rig with a stylish 12V LED light bar—we comprehend that selecting the correct wire gauge is not just wise, it’s essential. But we don’t stop there. Color-coded wiring? That’s our reliable companion for straightforward identification and ensuring no wires get mixed up, literally. It’s a vibrant world, and we fully embrace it, especially regarding our impressive LED configurations. Now, let’s dive into the dazzling realm of color codes and insulation ratings!

Decoding the Wire Color Codes

Our eyes aren’t just for appreciating the brilliance of our LEDs; they are also prime tools for interpreting the spectrum of wires we’ve got. Red or black typically shouts, “Hey, I’m live, handle with care!”, while neutral wires often appear in neutral shades like brown or white. However, it’s the yellow-green combination that proclaims loudly, “I’m grounded!” So, avoid mix-ups here, folks.

And just a quick note, even our supposedly neutral wires can harbor a hidden current when least anticipated. It’s like discovering that your quiet friend is secretly a superhero… or a daredevil. Remember to switch off that power source before plunging headfirst into the wiring tasks.

Exploring Insulation Types and Their Importance in Wiring

Let’s discuss what envelops our wiring: insulation. It’s not just about keeping our wires snug; it’s about ratings and safety. Insulation ratings are the secret handshake in an electrician’s realm—they inform us how much voltage our wire’s coating can withstand before it sparks an uninvited light show (spoiler: fire is undesirable).

| Wire Color | Use Case | Insulation Rating |

|---|---|---|

| Red/Black | Live Wires | Vary by insulation type |

| Brown/White | Neutral Wires | Vary by insulation type |

| Yellow/Green | Ground Wires | Vary by insulation type |

Like a dependable map guiding us through the electrical wilderness, insulation types indicate whether our wiring is prepared for the journey to LED light bar paradise or if it might take an unexpected detour. You get the idea, right? Pay close attention to those coverings. Choose wisely to ensure accurate electrical connections and keep your setup operating smoothly. That’s how we navigate our 12V electrical endeavors with grace and confidence—and, most critically, without getting burned in the process.

Conclusion

We’ve explored the intricacies of professional wiring for LED light bars, and by now, it’s clear that optimal wire selection for LED…

“““html

Light bars is the cornerstone of both efficiency and security. Guaranteeing security in 12V LED configurations isn’t solely about following regulations; it involves grasping the subtleties of electrical systems. Every wire gauge choice should demonstrate a balance between electrical principles and practical implementation that only genuine craftsmanship in the field can accomplish.

Attaining optimal LED bar efficiency resembles orchestrating a concert—the correct wire gauge is our conductor, and the electrical flow is our ensemble. When we choose wire gauge with care and anticipation, we become maestros of brilliance, ensuring that each LED bar in our array reaches the pinnacle of luminosity and effectiveness while preserving a consistent tempo of safety and dependability.

Thus, let’s remember, as we conclude, that our purpose goes beyond the illumination of LEDs. We are the guardians of the hidden yet vital channels of energy in our lighting systems. By making educated decisions regarding load capacity, voltage losses, and the challenges we face, we don’t merely install light bars; we instill enduring confidence within every illuminated area.

FAQ

What wire gauge is advisable for a 12V LED light bar?

Typically, we prefer to err on the side of caution and frequently recommend a 14 or 16 gauge wire for most small to medium-sized 12V LED light bars. However, the ideal wire gauge for your 12V LED light bar will depend on the specific demands of your setup, including the total wattage of the light bar and the length of wire required.

Why is selecting an appropriate wire gauge critical for my LED light bar’s electrical system?

Choosing the correct wire gauge for your 12V LED light bars is essential because it affects how effectively your system can conduct electrical current. A wire that’s too thin can overheat, which is a significant concern—we’re talking about potential fire dangers here. Conversely, a wire that’s too thick may be excessive and cost-prohibitive, not to mention trickier to manage during installation.

Can you clarify the distinction between solid and stranded wires for LED lighting?

Certainly, let’s simplify it: solid wire is, as the name suggests, solid—making it less flexible, yet easier to install. Stranded wire, in contrast, is like a bundle of thinner wires twisted together, offering more flexibility but can sometimes complicate connections. Both have their moments to shine when it comes to LED light bar setups.

Why is it vital to assess wire gauge based on current load and voltage drop?

This point is crucial: you want to ensure that the wire you select can manage the current that your 12V LED light bar draws without overheating (indicating too much resistance which can induce voltage drop). Why is this important? Because resistance converts electrical power into heat, and excessive heat can cause issues like diminishing your light bar’s brightness or even creating a fire hazard. It’s all about achieving that ideal equilibrium in wire gauge so you can sit back, relax, and appreciate the illumination without anxiety.

When should I opt for stranded over solid wire for my 12V LED application?

If you’re maneuvering your wire through confined areas, winding routes, or angles that would impress even a gymnast, stranded wire is your best bet. If your installation is more straightforward and doesn’t require much bending or flexing, solid wire might be your ideal companion—it’s simpler to work with during connections.

How can I ascertain the right wire gauge for my LED light bar setup?

Grab your calculators; it’s time for some math! First, determine the total wattage of your LED light bar and divide it by 12 (volts) to find the current in amperes. Next, take into account the length of wire you will use. With those two figures in hand, you can consult a wire gauge chart that will guide you. It’s like a treasure map, but instead of X marking the spot, it’s the correct wire gauge for a brilliant LED treasure.

Does wire gauge size impact my LED light bar’s performance?

Definitely, a wire that’s too thin can cause the voltage to drop significantly—except it’s not exciting, it’s actually dimmer. This can lead to your LED light bar performing at a lesser brightness than a second-rate performer. Choosing the right gauge guarantees your LEDs shine to their fullest and have a longer lifespan.

What are the dangers linked to using an incorrect wire gauge?

The risks of selecting an inappropriate wire gauge are akin to serving an overcooked steak to a fine dining chef—not ideal. Using a gauge that’s too thin for the appetite of your light bar? Welcome to overheating and potential fireworks! Plus, you might end up with lights as dim as a fog-laden night in San Francisco. Don’t let your light bar down—choose wisely!

What are your top suggestions for wire thickness and installation approaches?

Choose generously or don’t choose at all—well, not quite. However, we recommend opting for a wire gauge that comfortably accommodates a bit more than the minimum current needed by your light bar. Think of it as future-proofing your setup and avoiding unnecessary heat—it’s like using both a belt and suspenders—extremely secure. When it comes to installation methods, neatness and adherence to safety regulations are paramount.

How does grasping wire size and color coding assist with electrical work?

Comprehending wire sizes and color coding is akin to knowing the secret handshake at an elite club—it gets you in and keeps you secure. Different hues indicate what role each wire plays in the larger electrical context. For example, black or red wires generally signify power, while green or green-with-yellow stripes is the international shorthand for “I’m grounded.” Familiarity with this colorful lexicon ensures a seamless installation and prevents you from making a shocking error.

“`

Isabelle

I think wire color matters more than gauge for LED light bars!