In this step-by-step guide, I will walk you through troubleshooting common issues with industrial LED lights. Industrial LED lights play a vital role in providing efficient and long-lasting lighting solutions for various industrial settings. However, they can sometimes encounter issues that may affect their performance. This guide aims to help you identify and resolve those issues, ensuring that your industrial LED lights continue to provide optimal lighting for your workspace.

Top-Rated Lighting Solutions for Industries

[content-egg-block modules=AmazonNoApi template=offers_grid cols=3 groups=”SectionIntro”]

A Guide to Troubleshooting LED Drivers

[content-egg module=Youtube template=responsive_embed hide=title,description limit=1]

Step 1: Identify the issue

To identify common issues with industrial LED lights, follow these steps:

- Check for flickering: Observe if the light is flickering or blinking rapidly. This could indicate a problem with the power supply or the LED driver.

- Test for dimming: Assess if the light output is significantly reduced compared to its normal brightness. This may suggest a faulty LED or a problem with the power source.

- Look for complete failure: If the LED light fails to turn on at all, be sure to check the power connection and the fuse. Also, consider inspecting the LED itself for signs of damage or burnout.Remember to always consult a professional if you are unsure or if the issue appears more complex than initially anticipated.

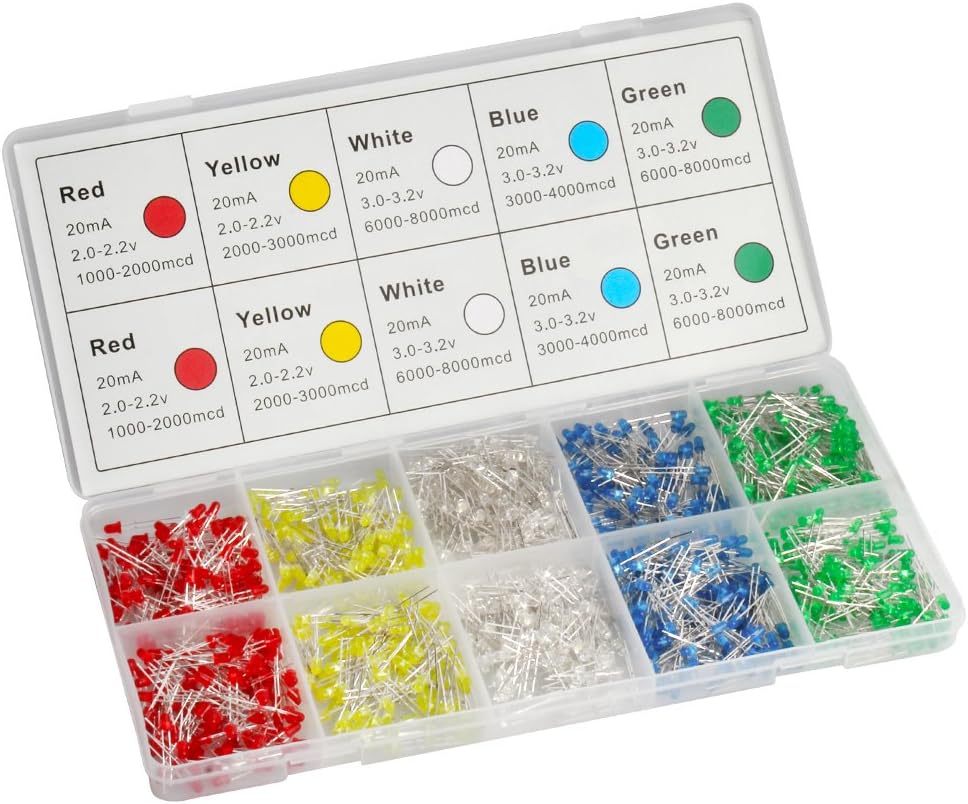

[content-egg-block modules=AmazonNoApi template=offers_grid cols=3 groups=”Step1″]

Step 2: Check power supply

To check the power supply and ensure it is functioning properly, follow these steps:

- Start by turning off your device and disconnecting it from the power source.

- Inspect the power cable for any signs of damage or fraying. If you notice any, replace the cable before proceeding.

- Plug the power cable securely into the outlet, ensuring a snug connection.

- Switch on the power supply and listen for any unusual sounds, such as buzzing or humming.

- Use a multimeter to measure the voltage output of the power supply. Compare the reading to the recommended voltage specified for your device.

- Repeat the voltage measurement while the device is turned on to check if the power supply is providing a stable current.

- If the voltage output or current is significantly off, you may have a faulty power supply and should consider replacing it.

By following these simple steps, you can determine if your power supply is functioning correctly and providing the necessary voltage and current for your device.

Step 3: Inspect wiring connections

Inspecting wiring connections is crucial to ensure the proper functioning of electrical systems. Start by visually examining each connection and look for any loose or damaged wires. If you find any, tighten the connection using a screwdriver or a pair of pliers. Alternatively, if the wire is damaged, replace it with a new one, making sure to strip the insulation and securely reconnect it. Remember to always turn off the power before working on electrical connections to ensure your safety.

[content-egg-block modules=AmazonNoApi template=offers_grid cols=3 groups=”Step3″]

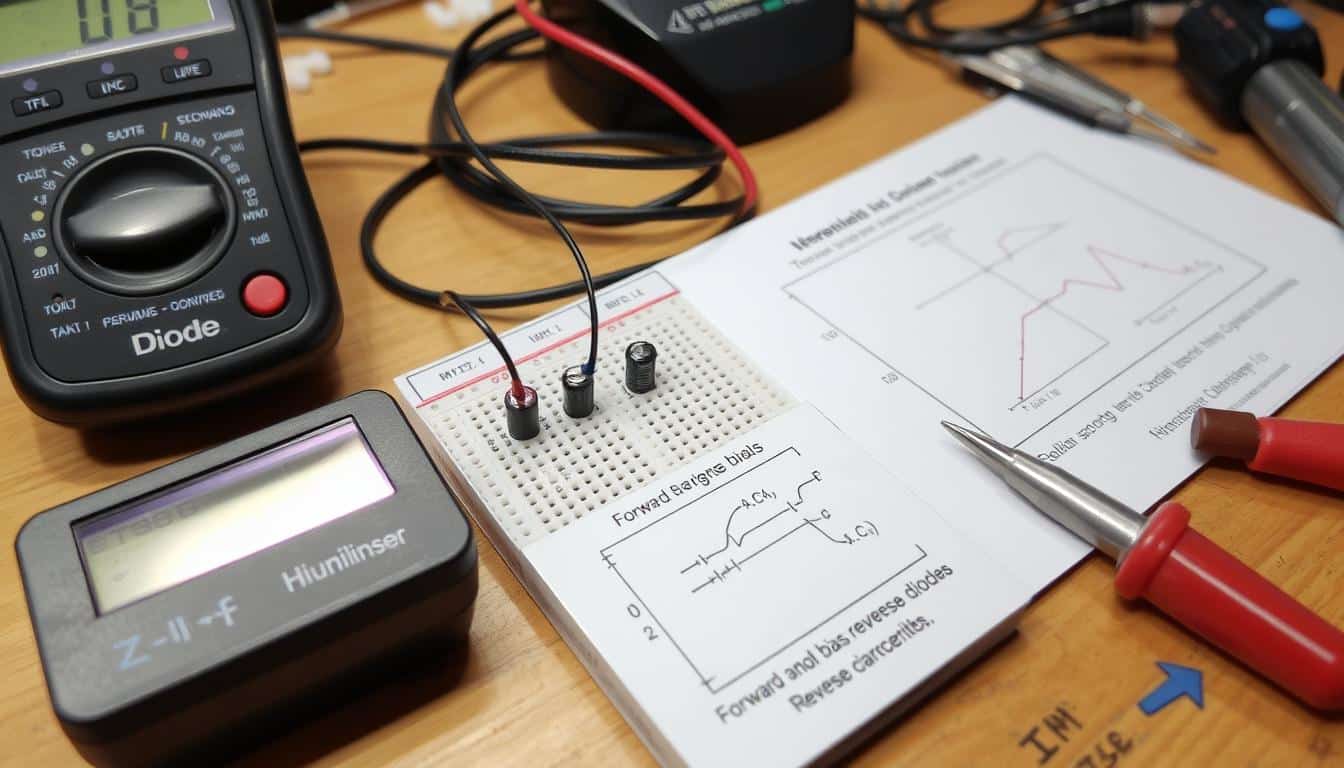

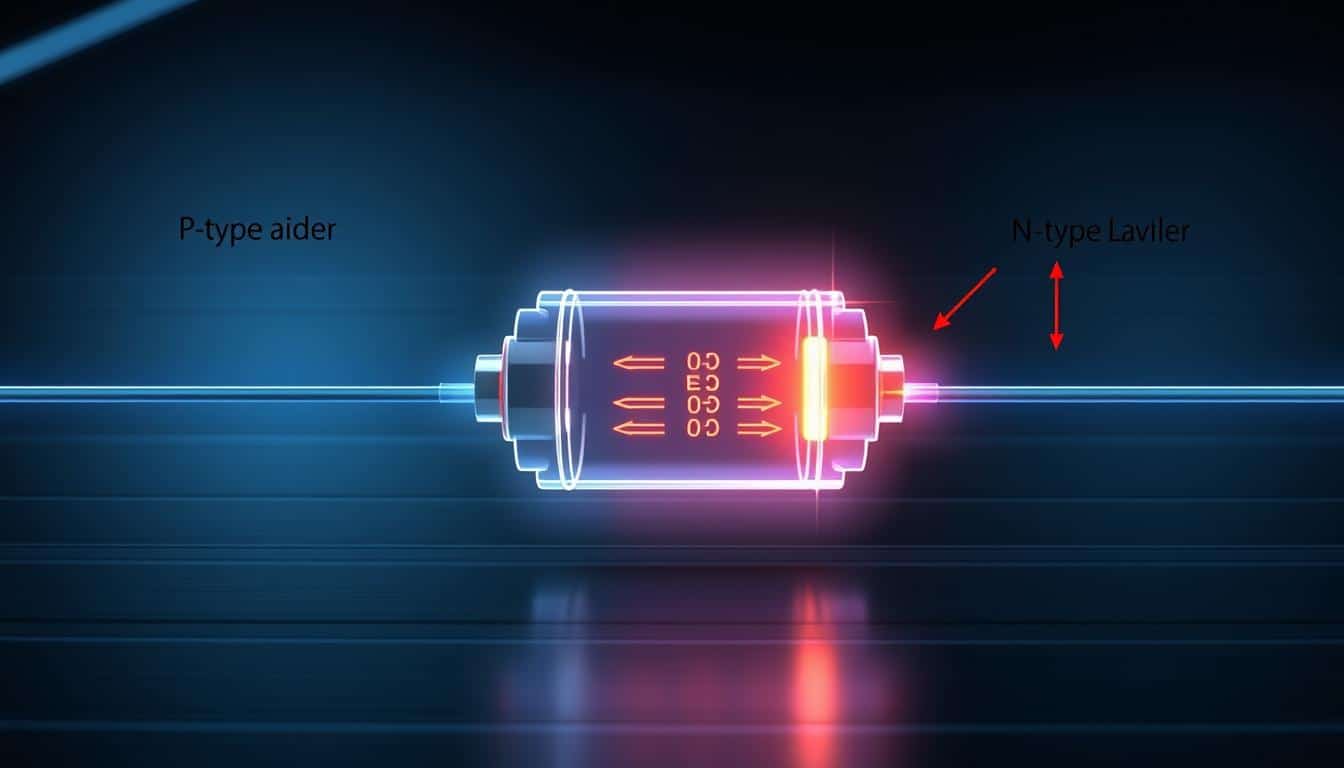

Step 4: Check the LED driver

To test the LED driver and ensure it is functioning correctly, follow these simple steps:

- Begin by disconnecting the power supply to the LED driver.

- Next, use a multimeter to measure the output voltage of the LED driver. Set the multimeter to the DC voltage mode and touch the positive (red) probe to the positive output terminal of the LED driver and the negative (black) probe to the negative output terminal.

- The multimeter should display a reading close to the rated voltage of the LED driver. For example, if the LED driver is rated for 12 volts, the multimeter should show a reading close to 12V.

- If the voltage reading is significantly lower or higher than the rated voltage, there may be an issue with the LED driver. In such cases, it is advisable to consult a professional or refer to the manufacturer’s troubleshooting guide for further assistance.

For example, if you measure the voltage output of a 12V LED driver and the multimeter displays 12.5V, the driver is supplying the correct voltage. However, if the multimeter shows a reading of only 10V, there may be a problem with the LED driver that needs to be addressed.

Remember, always exercise caution when working with electrical components and consider seeking professional help if you are unsure or uncomfortable performing these tests.

Step 5: Assess the heat dissipation

Assessing heat dissipation is crucial for ensuring the proper functioning and longevity of industrial LED lights. Efficient heat dissipation prevents overheating and keeps the lights performing at optimum levels. To check for any issues, carefully inspect the fixture for any signs of excessive heat, such as discoloration or burnt components. Additionally, ensure that air vents are free from obstruction and clean, as restricted airflow can hinder heat dissipation.

Step 6: Inspect the LED modules

To inspect the LED modules for any signs of damage or malfunction, first, visually examine each module for dead LEDs or any discoloration. Take note of any abnormalities or irregularities you observe. Then, if possible, test the functionality of the modules by providing power to them and observing their behavior. Look out for flickering LEDs or any other signs of malfunction.

Step 7: Test the control system

To test the control system and its components such as dimmers or sensors, follow these steps:

- Verify power supply: Ensure that the control system is receiving power by checking the main power source and any related circuit breakers.

- Inspect connections: Check all the connections between the control system and the dimmers or sensors. Make sure they are properly seated and securely connected.

- Test dimmers: Begin by turning on the lights connected to the dimmers. Use the control system to adjust the dimmers to different light levels. Verify that the lights respond accordingly and smoothly without flickering or abrupt changes.Example: Turn on the lights and gradually increase the dimmer level to 50%. Observe if the lights dim as expected. Repeat this process at various dimmer levels.

- Test sensors: If your control system includes sensors, ensure they are properly positioned and functioning. For motion sensors, walk in front of them to check if the lights are activated. For light sensors, cover them and observe if the lights turn on.Example: Walk in front of a motion sensor and check if the lights turn on within a specified time frame. Cover a light sensor and confirm if the lights are triggered or adjust according to the ambient light level.

- Check for system issues: Pay attention to any unusual behavior or error messages displayed on the control system interface. Check if any buttons or controls are unresponsive or not functioning as intended.Example: Press different buttons on the control system interface and observe if they perform the corresponding actions. Take note of any error messages or abnormal system behaviors.

By following these steps, you can ensure that your control system, including dimmers and sensors, is functioning properly and not causing any issues.

Step 8: Seek professional assistance if needed

Step 8: Seek professional assistance if needed.

Sometimes, certain electrical issues or repairs can become more complex than anticipated. If you find yourself in a situation where you are unsure how to proceed or if the issue requires specialized knowledge, it is best to seek the help of a professional technician or electrician. They have the expertise and experience to handle more intricate electrical problems safely and efficiently. Don’t hesitate to reach out to them for assistance—their expertise will ensure a job well done.

Wrapping it all up

In conclusion, troubleshooting common issues with industrial LED lights is crucial for maintaining their efficient and reliable performance. By following the steps outlined in this guide, you can identify and resolve problems such as flickering, dimming, or inconsistent lighting. Remember to check connections, power supply, and control systems, as these are often the culprits behind these issues. Additionally, regular cleaning and maintenance can greatly extend the lifespan of your LED lights. By being proactive in troubleshooting, you can ensure optimal illumination and avoid costly repairs or replacements.

Expert Advice

Step-by-step guide to effectively utilizing Industrial LED lights

- Begin by selecting the appropriate Industrial LED lights for your specific needs. Consider factors such as the size of the area you want to illuminate, the desired brightness level, and any specific features you may require

- Once you have acquired the Industrial LED lights, carefully read the manufacturer’s instructions and familiarize yourself with the product. Pay attention to any safety guidelines or precautions mentioned

- Before installation, ensure that the power source is switched off to avoid any electrical mishaps. Industrial LED lights typically require a connection to the electric grid, so you may need to consult an electrician or follow specific wiring instructions

- Install the Industrial LED lights securely in the desired location, ensuring that they are positioned correctly for optimal lighting. Some lights may need to be mounted on walls, ceilings, or poles, while others may come with stands or brackets for placement on surfaces

- Finally, once the Industrial LED lights are properly installed, you can switch on the power and test the lighting. Check all the settings and controls to ensure that they are working as intended. You may also want to explore additional features such as adjustable brightness or timers, depending on the specific model

- Remember, always prioritize safety when handling electrical equipment and consult professionals if needed. Enjoy the energy efficiency and long-lasting illumination provided by your Industrial LED lights!

Moonchild

One tip I would add is to regularly clean the heat sinks and fans of the LED lights. Dust and debris can accumulate over time, affecting the heat dissipation and potentially causing performance issues. Regular maintenance can help prolong the lifespan of the lights and prevent overheating. Great guide overall!