Have you ever wondered if you can cut LED lights and still have them work perfectly? Maybe you want to customize the length for your room, or fit them into a unique space.

It’s a common question, and the answer isn’t as simple as you might think. If you cut them the wrong way, you could end up with lights that don’t turn on or flicker. But don’t worry—this guide will show you exactly how to cut LED lights safely and keep them shining bright.

Keep reading to discover the easy tricks that will save you time, money, and frustration.

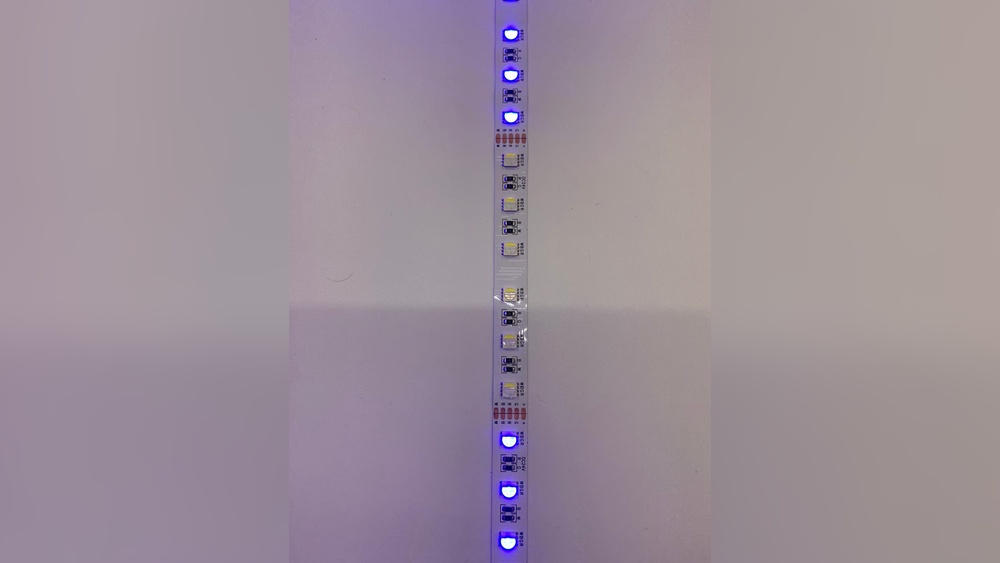

How Led Strips Are Designed

Understanding how LED strips are designed helps explain if you can cut them and still use them. LED strips come in flexible rolls with small lights and electronic parts. These parts work together to produce light while allowing customization for size and shape. The design includes clear cutting points that let users trim strips safely. This design makes LED strips popular for many lighting projects at home or work.

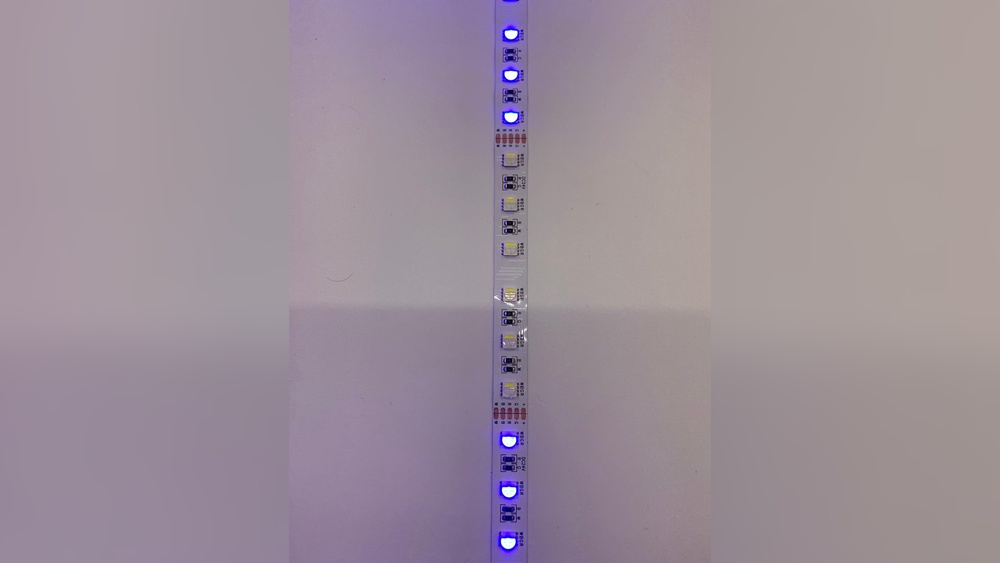

Led Strip Components

LED strips contain several key parts. The small lights are called LEDs, placed evenly along the strip. Copper pads connect the LEDs and carry electricity. A thin circuit board holds the components in place. Sometimes, a protective layer covers the strip to prevent damage. Each component plays a role in making the strip work properly and safely.

Cutting Points Explained

Cutting points are marked spots on the LED strip. They usually appear as small lines or scissors icons. These points show where you can cut without breaking the circuit. Cutting at these points separates the strip into smaller sections. Each section keeps working if connected to power correctly. Cutting elsewhere can damage the strip and stop it from lighting up.

Cutting Led Lights Safely

Cutting LED lights can help customize their length for your space. It keeps the lights working well without damage. Doing it safely is important to avoid breaking the circuit or hurting yourself.

Follow clear steps and use the right tools. This makes the process simple and safe. Prepare well before starting to cut LED strips.

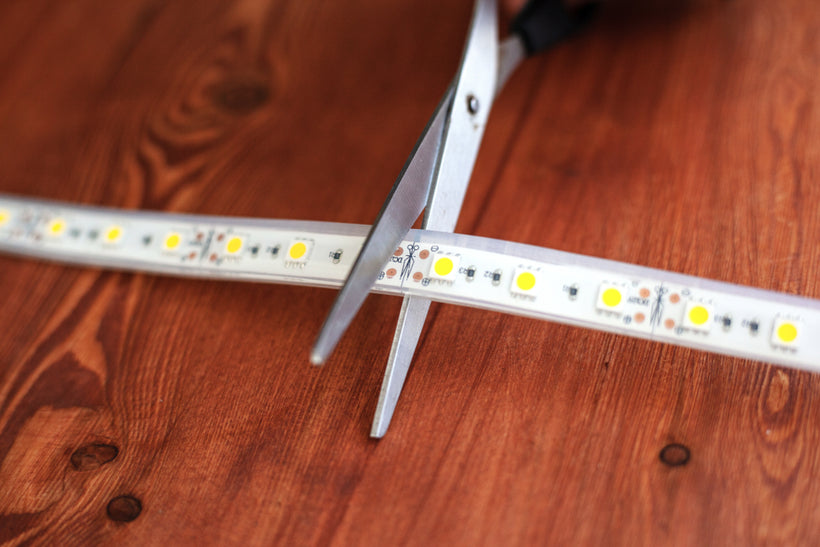

Tools You’ll Need

- Sharp scissors or a craft knife

- Measuring tape or ruler

- Marker or pen for marking cut points

- Optional: soldering iron for reconnecting cut strips

- Power supply to test the lights after cutting

Step-by-step Cutting Process

- Unplug the LED strip from the power source.

- Find the marked cut lines on the strip.

- Measure twice to ensure correct length.

- Use scissors or knife to cut exactly on the line.

- Check the cut edges for any damage or loose parts.

- Reconnect the strip if needed using solder or connectors.

- Plug in the strip and test the lights immediately.

- Secure any loose wires or ends safely.

Will Cut Led Strips Still Work?

Will cut LED strips still work? The short answer is yes, they can work after cutting. LED strips are designed to be flexible in length. This allows you to trim them to fit your space. But some care is needed to keep them working properly.

Each LED strip has specific cutting points. These spots are marked with small lines or scissors icons. Cutting only at these points helps keep the electrical circuit intact. Cutting anywhere else might damage the strip and stop it from working.

Electrical Connections After Cutting

Once you cut the LED strip, you must connect the cut end to a power source or another strip. Use the copper pads at the cut points for this. You can solder wires or use special connectors made for LED strips. These connections carry electricity to light up the LEDs.

Make sure the connections are secure and match the strip’s polarity. Polarity means the positive and negative sides must align correctly. Wrong polarity can cause the LEDs not to light or even damage the strip. Proper connections also prevent flickering or dim lights.

Common Issues To Watch For

Some common problems happen after cutting LED strips. Loose connections are a frequent cause of failure. The strip might light up only partly or not at all. Check that wires or connectors fit tightly on the copper pads.

Another issue is cutting in the wrong place. This can break the circuit and stop power flow. Avoid cutting through the LEDs or resistors on the strip. Also, ensure the power supply matches the strip’s voltage needs. Too high or too low voltage can cause damage or poor performance.

Reconnecting And Extending Cut Leds

Cutting LED strip lights can be useful for fitting them into tight spaces. After cutting, you can reconnect and extend the strips to make them work again. This process lets you customize the length and shape of your LED setup. There are simple ways to join cut strips without losing brightness or color quality.

Reconnecting cut LED strips requires care. Proper connections ensure the lights shine evenly. Two common methods are using connectors or soldering the wires. Both methods keep the electrical flow steady. This helps the LEDs work as if they were never cut.

Using Connectors

Connectors are quick tools for joining LED strips. They snap onto the ends of the cut strips. This avoids the need for tools or wires. Choose connectors that fit your LED strip size and type. Slide the strip into the connector and lock it in place. Make sure the metal contacts touch the strip’s copper pads. This ensures power flows through the connection. Connectors work well for simple, straight joins or slight bends.

Soldering Tips For Beginners

Soldering creates a strong, reliable connection between cut LED strips. Use a small soldering iron with low wattage. Heat the copper pads gently to avoid damage. Apply a little solder to the pads before joining wires or strips. This is called “tinning” and helps the solder stick better. Connect the positive and negative wires carefully, matching the strip’s polarity. Hold the wires steady until the solder cools. Avoid cold joints by heating the parts enough for a smooth finish. Soldering takes practice but offers a secure and neat connection.

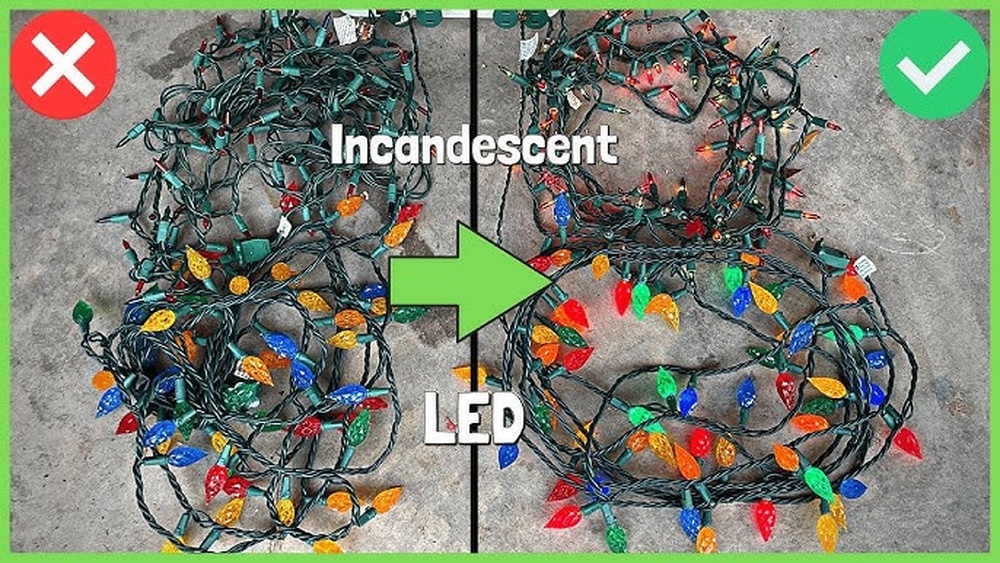

Power Supply Considerations

Power supply plays a big role when you cut LED lights. It needs to match the new length of the strip. Otherwise, the LEDs may not work well or could get damaged. Understanding power supply needs helps keep your lights bright and safe.

Adjusting Power For Shorter Strips

Shorter LED strips need less power. The original power supply may provide too much energy. This can cause overheating or reduce the strip’s life. Use a power supply that fits the new strip length. Check the voltage and current ratings carefully. Use a smaller power supply or add a resistor if needed.

Avoiding Overload And Damage

Too much power can harm LED strips. It may burn out the LEDs or cause flickering. Avoid connecting a long strip to a power supply meant for a shorter one. Always match the power supply to the total wattage of the cut strip. Use a proper connector and avoid loose wires. These steps help prevent damage and extend LED lifespan.

Creative Uses For Cut Led Strips

Cut LED strips open many creative doors. They let you shape light to fit your needs. Small pieces of LED strips still work well after cutting. This flexibility inspires fun and useful projects. You can design unique lighting setups for any space. Their adaptability makes them perfect for both art and function.

Custom Lighting Designs

Cut LED strips allow for tailored light shapes. You can fit light into tight corners or odd spaces. Create patterns that match your style or room shape. Use them to highlight shelves, stairs, or artwork. These strips help bring your lighting ideas to life. They fit perfectly in places standard lights cannot reach.

Decorative And Practical Applications

Cut LED strips brighten more than just rooms. Use them to decorate furniture edges or mirrors. They add charm and warmth to any setting. Practical uses include under-cabinet lighting in kitchens. Illuminate closets or workspaces for better visibility. These strips combine beauty with everyday usefulness.

Troubleshooting Cut Led Strips

Troubleshooting cut LED strips can be simple with the right approach. Many people cut LED strips to fit a space. Sometimes, the cut sections do not light up. This problem can happen due to several reasons. Knowing how to find and fix these issues saves time and money.

Diagnosing Non-working Sections

Check the cut edges first. Look for any damage or loose connections. Use a multimeter to test continuity across the cut points. No continuity means a break in the circuit. Inspect the solder joints or connectors at the cut area. Sometimes, poor soldering causes the LEDs to stop working. Also, check the power supply. Insufficient power can cause parts of the strip to fail. Verify the polarity is correct. LED strips need the right positive and negative connections. Wrong polarity may prevent lighting on cut sections.

Fixes And Preventive Tips

Use proper tools to cut the strip exactly on marked lines. Always solder or use quality connectors to join cut parts. Test the strip after each cut to catch problems early. Avoid stretching or bending the strip sharply near cut points. Keep the power supply strong enough for the total length. Use a multimeter to ensure good electrical flow. Seal solder joints with heat shrink or tape to protect from moisture. These steps reduce chances of non-working sections after cutting.

Frequently Asked Questions

Can Led Lights Be Cut Without Damaging Them?

Yes, LED lights can be cut at marked points without damage. Cutting elsewhere may break the circuit and stop them from working.

Where Should You Cut Led Strip Lights Safely?

Cut LED strip lights only at designated cutting marks. These marks ensure the electrical circuit remains intact for proper function.

Will Cutting Led Lights Affect Their Brightness?

Cutting LED lights properly does not affect brightness. However, improper cuts may cause sections to lose power or not light up.

Can You Reconnect Led Lights After Cutting?

Yes, you can reconnect LED lights using soldering or connectors. Proper reconnection restores the circuit and allows lights to work again.

Conclusion

Cutting LED lights can work if done carefully and correctly. Always cut only at the marked spots on the strip. Use the right tools to avoid damage. After cutting, connect the strips properly to keep the lights on. Remember, not all LED strips are made for cutting.

Check the product details before you start. This way, you get the perfect length without losing light quality. Simple steps make your LED project easy and successful. Enjoy bright, customized lighting that fits your space well.

Leave a Reply